Hope everyone’s enjoying family time right now. I was holding onto this update because it seemed too short. Then I remembered that our long updates are about all the things that have gone wrong, and the systems that we have to navigate. No problems this time, so short it is. Mechanicals One of our bigger… Continue reading 10,000 things being made

Things moving around the world

Got a shorter update than usual as we’ve mostly been waiting and managing logistics, which I’ve written enough about to bore even myself to tears. Manufacturing The factory test/programming rig got to the assembler pic along with some “golden master” boards that they can use as a working baseline. We probably have some bugs and… Continue reading Things moving around the world

Materializing

We’re in that lull I warned about last update. We’ve been focused on production setup, and such a range of emotions we’ve been through. Buttons Exciting! Got sample silicone buttons. They fit nicely and diffuse light well. Disappointing! The action on these is really stiff with too much travel. That’s okay—this is why we get samples. Exhausting! I’ve… Continue reading Materializing

Button pushing

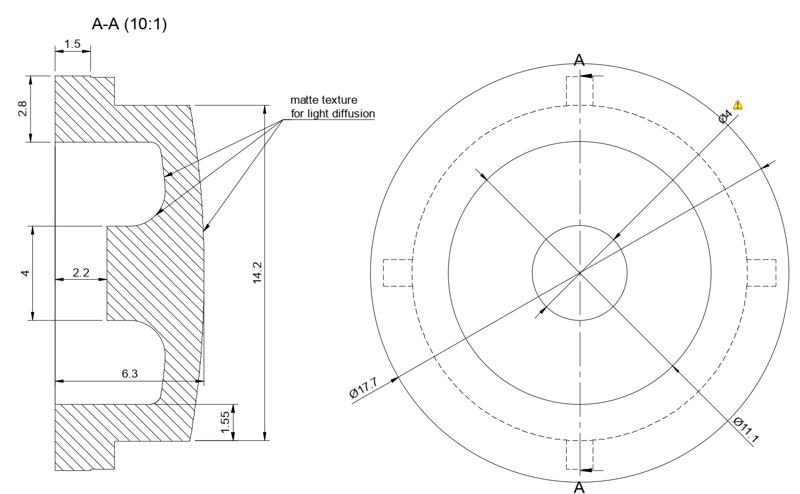

Apologies for the later update. We’ve got slow but real progress on mechanicals and production test systems. Mechanicals Another round of parts just arrived in the mail, as I try to adjust the design for MJF printing. MJF is not as stiff as the injection molded polycarbonate and doesn’t handle the fine details as well,… Continue reading Button pushing

Granular

Slow progress lately. Maybe it’s the summer schedule. Maybe it’s because I’m back on the mechanical track. Multi-jet fusion: it’s different The new printed parts took a while to get to me (I suspect they had to reprint some), and I’m painstakingly measuring expected vs actual critical dimensions (an engineering term meaning the dimensions that… Continue reading Granular

Scrambling up the supply chain

It’s a tentative relief to have a new plan for Pickup’s case plastics settled. The other major unknown is costs from tariffs, as well as the knock-on effects on the global supply chain. This has easily been the largest number of components we’ve ever had in a project, when you consider the 8 plug-in cartridges,… Continue reading Scrambling up the supply chain

A path forward on plastics

We told our injection molding partner to stop tool production—if there was anything to stop—and requested our deposit back. It’s a shame. I picked a local molder because I wanted a quick iteration loop, but it turned out they didn’t have the expertise here and they ended up being an intermediary between me and a… Continue reading A path forward on plastics

Sensor party 2

More on sensor cartridges—we’ve been testing, debugging and polishing, and we’re close to starting production on the circuitboards for all of these. Particulate/VOCs This one had some twists. We had planned on using a smaller particulate sensor that was announced just last year. As is often the case, the announcement comes well before the details.… Continue reading Sensor party 2

Tariffs don’t make you competitive

As a snapshot of what makes Asian manufacturing hard to beat, the prototype boards for Pickup’s temperature cartridge are taking seven days door to door. That includes making our circuitboard, assembling the components on it, and shipping overseas, for under $15 a board. In my experience, you’d be lucky to get a quote from a domestic assembler… Continue reading Tariffs don’t make you competitive

Sensor party

To make up for those boring logistics updates, we have tangible movement on actual stuff this time. Unfortunately not case plastics, but a bit of just about everything else. The case molds are still stuck in a backlog. The molder says, “They [the mold maker] are telling me they have had sole delays due to… Continue reading Sensor party