The hardware is solid now, and final hardware development is wrapped up. Next, we’re making the tools for production. Read on for what we’ve been up to.

Mechanicals

The final prototype came out nicely. It feels even better than it looks, as you can infer from Jeremy’s expression when I handed him the assembled final prototype.

There were a couple changes, all expected after testing how the components fit into the final case prototype. Our preliminary final design was sent to the mold maker three weeks ago for their review, but I hadn’t heard back from them. No matter, I wasn’t waiting for them while I made those final fit changes. At the end of last week, I sent the _final_ final design files to the mold maker and nudged them. I’m expecting an answer this week. Once they approve of the adjustments I made, the mold gets cut. They’re promising 6 weeks to sample parts.

The mechanicals have been a hard slog as I’ve worked to make the best plastic parts I’ve ever done, but (pending that mold maker approval, and yes, inspection of the first injection molded parts) it’s done. I’m looking forward to showing you the samples.

Electronics

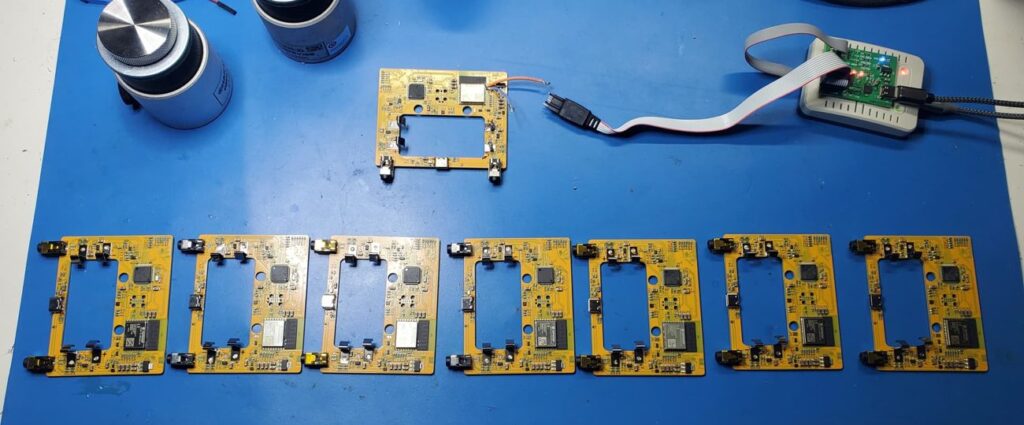

Jeremy got more mainboards up and running. Programming/self tests pass on 9 out of the 10 in the batch. The 10th is probably fixable, but he just hasn’t had time to investigate it yet.

In concert with my case adjustments, Jeremy’s been moving around components for what is hopefully our final board rev. The boards above are working great — I just needed room for other components when they’re assembled in the case. I did have a concern with the batteries sometimes snagging on the contacts when inserted, and if forced, the battery contacts would tear off in some cases. We increased space between the contacts, strengthened the attachment points, and some other small tweaks to address this.

So we’re happy with the board design. The next step will be a small production run of 50-100 boards, and Jeremy’s talking with our PCB partner about that right now.

Along with that, he’s working on the production test system that the factory will use to verify they have assembled each board correctly. Much of it is the same electronics that Pickup already uses, packaged in a different way and running slightly different software. Since it reuses so much of Pickup’s components, subcircuits, firmware and tools, it’s a relatively quick and easy design for Jeremy. In fact, he has already done it — assembled boards are back on their way to us right now. More on testing as a whole ‘nother product in the next post.

External battery / power

In the forum, a few backers have asked about power sources other than batteries:

Any possibility of using an external battery with solar so we can keep the higher data rate? Like a couple of V in pads on the board? That way if you wanted to hack it and add supplemental power (void warranty) it would be an easy hack? I can see using a rechargeable battery and an external MMPT charger and solar panel.”

I’ll repeat the answer here in case anyone else is wondering: Pickup has a USB-C power port, and yes, you can run it off an external battery (or a power outlet) that way.

Separately, another reason we don’t want full speed on all the time is that at 10 samples/second, at some point the bandwidth and storage needed for that becomes excessive. We’ll give early customers as much bandwidth as we can, but if you need a greater data rate, you can always send the data to another system instead.

Firmware

Jeremy’s got a lot of low-level stuff done (with firmware, I suppose it’s all low-level), but a quick summary of some interesting bits being built:

- Text-based configuration. I can change some of the behavior of Pickup over MQTT now, with much more flexibility to come. I’m building the friendly interface on top of this, but it’s there if you need it.

- Wildcards. With one command, you can configure multiple Pickups to perform the same behavior, such as filter and log data to a certain location.

- Over-the-air updates. Mostly for our development ease right now.

- Module detection and communication.

Software

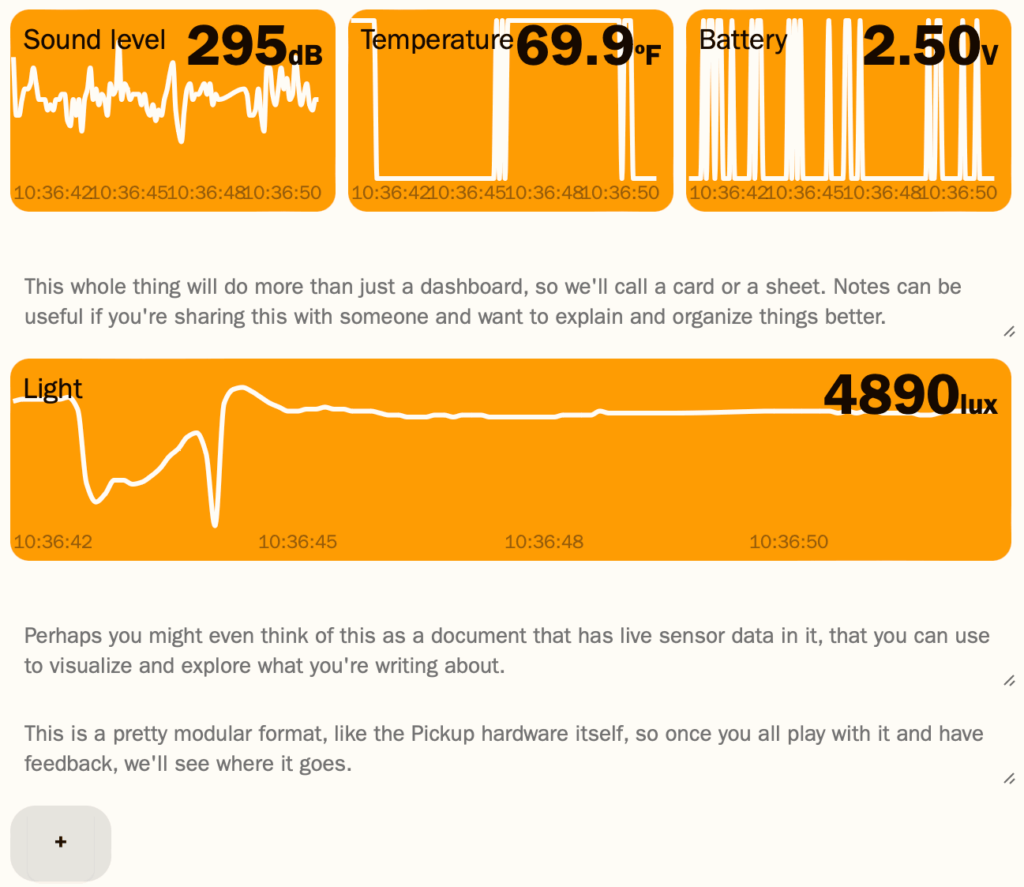

I’m only just turning my focus back to software, but an area I’m working on right now is flexibility to how you can display data from Pickup. It can be more than just a dashboard! If this gives you any ideas, I’d love to talk about them in the forum.

Now we’re lining up the items to start production, and in the next update I should be able to talk about reasonable timelines for manufacturing and delivering Pickup. Once again, we’re thankful for your backing and patience as we make a whole new thing that hasn’t existed before.

Crossposting from Pickup Kickstarter update #8