To make up for those boring logistics updates, we have tangible movement on actual stuff this time. Unfortunately not case plastics, but a bit of just about everything else.

The case molds are still stuck in a backlog. The molder says, “They [the mold maker] are telling me they have had sole delays due to a massive glut of molds being built. I am very frustrated about this situation. We haven’t had these kind of delays before although we have had some. We have never failed on a mold build and I’m going make sure we don’t fail you.”

It’s increasingly maddening, but he’s checking with them twice a week, and we can always find work to do while we’re waiting. Oh—here’s some of it now:

Cartridge first articles

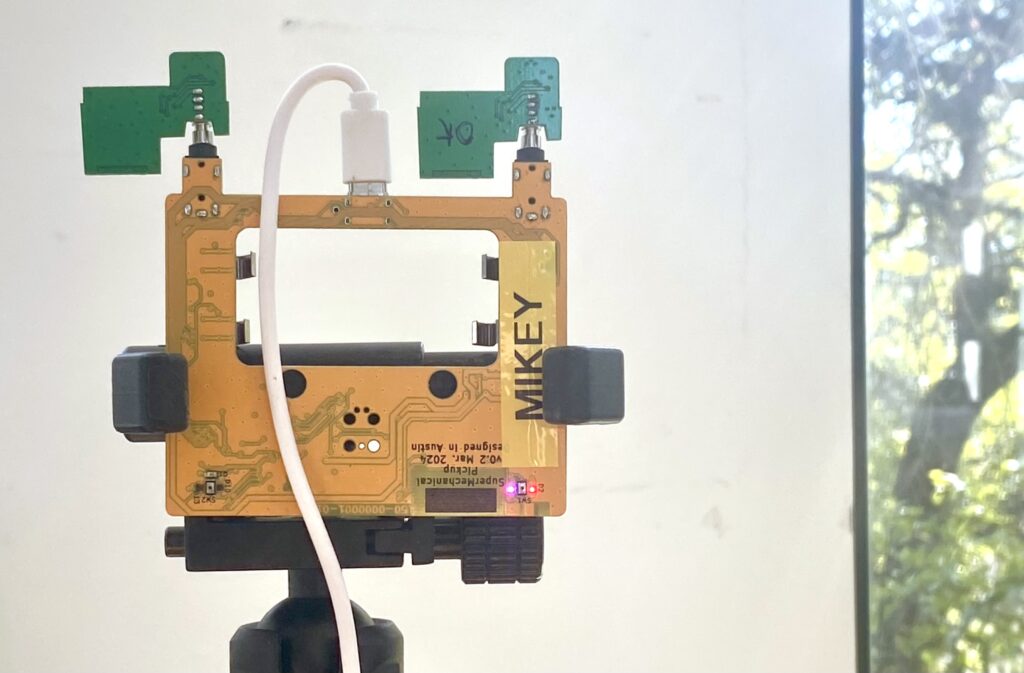

Nice thing about making hardware is the periodic Christmas of getting new parts and seeing how they work. We’ve got the first candidates for production parts on all our sensor boards and the cases, and we’re working them out to see what final tweaks are needed. TL;DR: A few tweaks are needed but no surprises.

We received four samples each of five of our sensor cartridges and they all work, which is nice.

Jeremy has all the sensors sending raw data, and is now tuning the firmware for each sensor. Some of them are pretty usable as-is, and some need refining (the spectral sensor is literally reporting the number of photons that hit it).

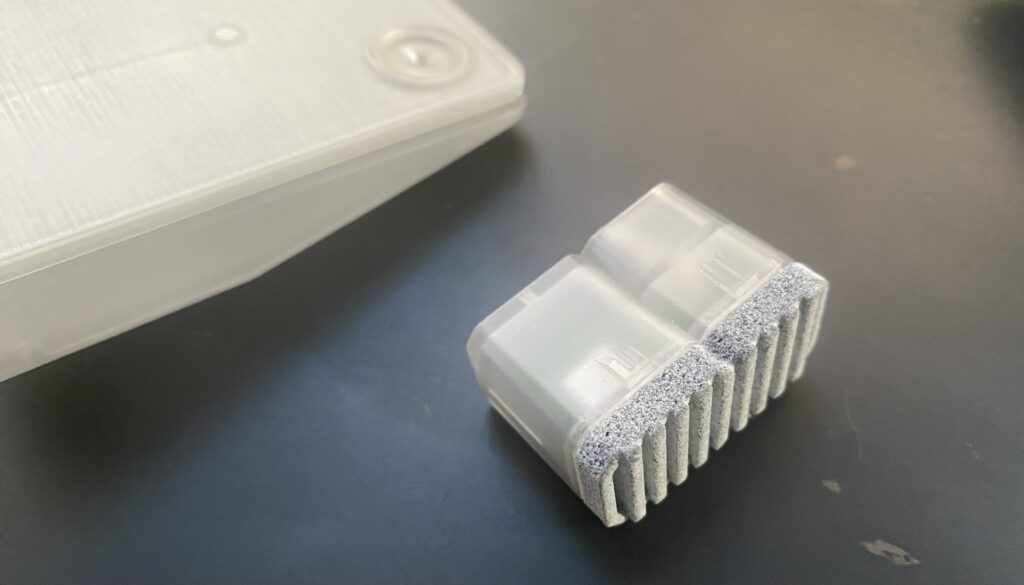

All the cartridge cases are made of a common injection-molded “bucket”, and a “fascia” unique to each. Each cartridge is too low-volume to injection mold the latter, so we’re using a production-quality MJF 3D printing process. It’s more expensive per part, but no mold production to throw off our whole timeline.

Let’s run through a couple of the cartridges as they are now.

CO2/humidity

Easy peasy. This one is compact and requires only circulation with the ambient air. No “interesting” requirements to add risk.

Distance

This one measures how long it takes a laser to bounce back to it. Pretty straightforward once you get past the miracle of timing something in picoseconds (i.e. trillionths of seconds). Only requirements are making sure the laser has clearance so it doesn’t bounce off the case, and adding a protective lens that’s transparent to the laser.

For some reason, the plug is .5mm longer than it’s supposed to be, which interferes with the lens placement. So a minor tweak on the board there, but we do have distance readings. I’m testing performance now with different lighting conditions and target objects (it’s supposed to work better with lighter, more reflective surfaces).

Moisture

This one’s fancy. It puts out a high-frequency capacitive field to measure water content in soil, or wherever. It works well so far, though we need to tune the raw data. We’ll explore its capabilities in more detail as we test it.

A little tight fit on the probes, but they’re custom made for us, so I had the factory add a bevel to ease assembly. Those probes have been made, and I just received them today.

Testing watertightness on the printed parts, it’s impressive how well the SLS-made parts diffuses water throughout, almost like a soaker hose. So that’s confirmation that MJF is the way to go.

I’ll talk about more sensor carts next time. Overall, there’s also some minor fit adjustments to make to all the boards (again, that plug not exactly matching the dimensional drawings). I need to get another round of samples printed, and I’d be surprised if I need a third.

Firmware

Jeremy’s also gotten more firmware infrastructure running. A lot of it has been boring but important stuff like data structures and the mechanisms to load and store configs on the device.

We’re always exploring the balance between flexibility and simplicity. If something’s too complicated, almost no one’s going to use it, and it also makes our work more difficult and time consuming.

Jeremy had a (pretty neat, to be fair!) custom syntax that could do some really powerful things, but it was only going to be useful if you had 100+ devices to configure, and was a bit overwhelming if you had 1 or 2—creating more work for us in order to solve a problem we didn’t actually have. (At least until someone buys 100 units!)

Now, our system is much simpler and fairly standard, using a human-readable JSON data structure. The config for one of the test devices looks like this:

Even if you don’t speak computer, you can probably guess what a lot of that does.

You’ll never need to interact with that directly (though part of our reasoning is that we do want it to be easy/approachable for users to create their own tools). Our app will handle low-level configuration for you. But it allows us to focus more on other things you’ll actually care more about.

This configuration data touches almost every part of our system in some way, so it was critical to get it right. It’s enabled us to move forward on a lot of other things, like the module boards. We need to be able to configure the modules in a flexible but simple way since you can swap out modules and have different settings for each type. We’ve thought about this problem for so long it’s easy to take for granted, but there’s no plug-and-play experience in a lightweight device like this!

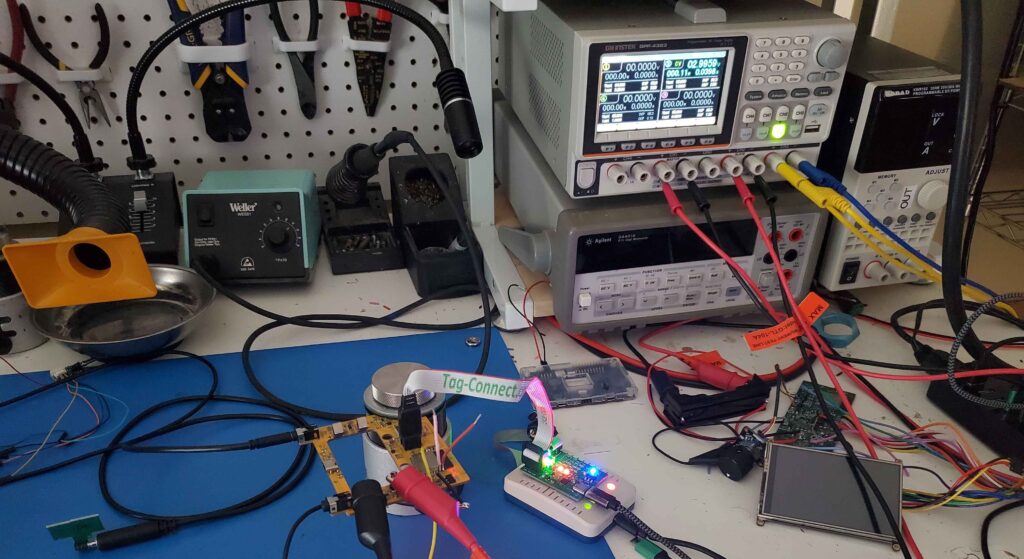

Debugging

Sometimes you need to have all the parts to test your idea, and find out whether it works in practice. While doing all of this work with the modules, Jeremy also finally tracked down a nagging glitch. When you plug/unplug a module, there’s a chance of the electrical contacts in the connector briefly short circuiting the power supply in Pickup, which sometimes causes the WiFi processor to restart.

The hardware is designed so this can’t damage anything, but Pickup would just hang up at this point, since of one of the CPUs stops and the other one didn’t know what to do. Now we can detect this and we just gracefully restart the WiFi if needed.

Tariffs update

An additional 10% tariff has been added to “everything” starting in February, according to a social media post. The exact categories were updated after the tariffs took effect (I don’t know how that’s supposed to work). Then this week, we got another post that says tariffs on Chinese goods will double on March 4. It’s in a quantum state until we get published changes to the Harmonized Tariff Schedule, and as it won’t ultimately change our path now, I’m mostly not trying to research exact amounts any more, and we’ll see how it shakes out as we get each component shipment. Hurray.

Reading list

If you have to stare at some videos on social media, MachinePix is excellent edutainment, fascinating snippets of industrial processes that make products and infrastructure. Sent me down a rabbit hole where I was watching 20-minute promo videos for giant pasta-making machines and self-running container ships.

Speaking of container ships, Tim Maughan’s Infinite Detail is a near-future novel that isn’t totally hopeless. How does the world work when we turn off the Internet? It’s lingered with me ever since I read it.

Thank you, dear backers, once again for your patience. From you to me to our San Antonio molder to the mold makers and whoever’s holding them up, we’re all frustrated. We don’t need to be in the world of Infinite Detail to appreciate how our world is a web of connected nodes. Maybe we didn’t need that reminder here and now, but all I can do is plug away at what I can control, and learn for next time. Progress is not always steady or linear, but we are getting closer.

Crossposted from Pickup Kickstarter update #14