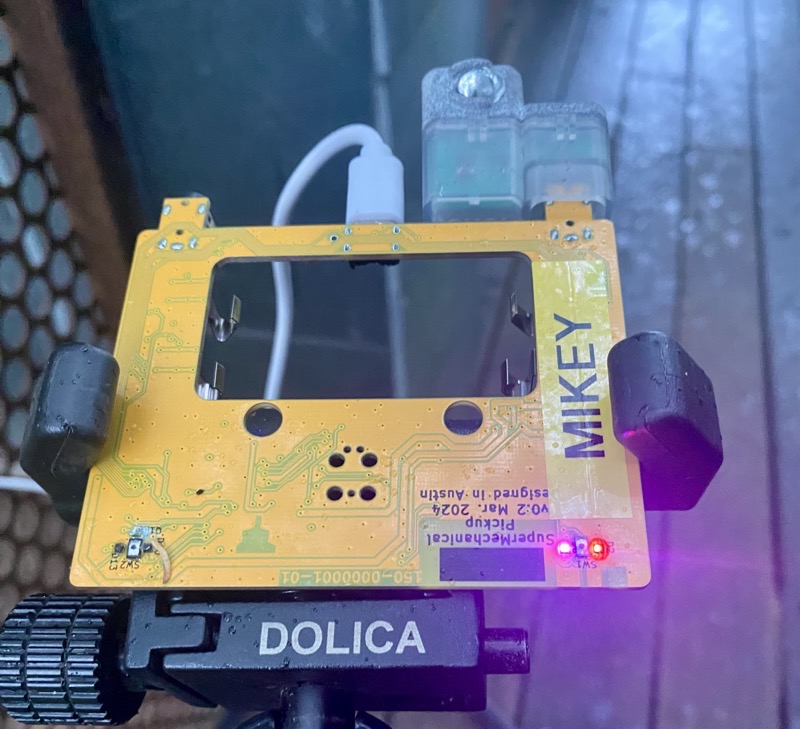

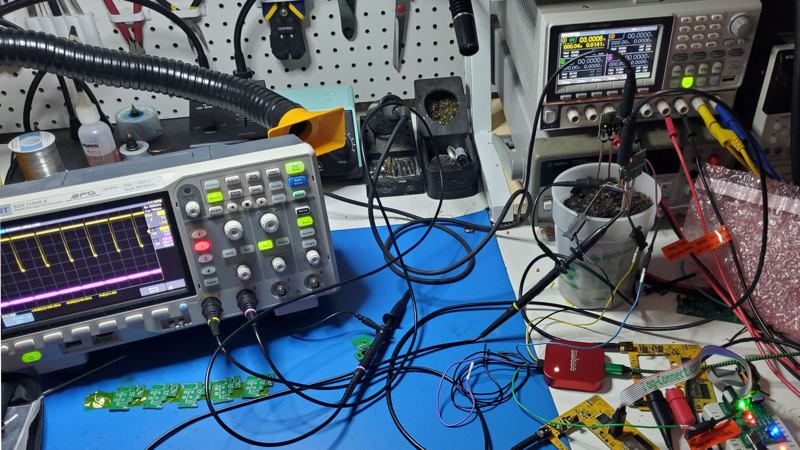

More on sensor cartridges—we’ve been testing, debugging and polishing, and we’re close to starting production on the circuitboards for all of these.

Particulate/VOCs

This one had some twists. We had planned on using a smaller particulate sensor that was announced just last year. As is often the case, the announcement comes well before the details. We finagled pre-production samples, and that let us discover that unfortunately, it required a more powerful (and power-hungry) microcontroller than what we’d already chosen for Pickup.

This was a calculated risk, with an existing sensor to fall back to. The downside is that it’s larger (virtually all particulate sensors have a chamber to pull in air to sample), but the upside is that it’s a proven technology and will give us more particulate sizes than just the one — 1.0, 2.5, 5.0, and 10 (all measured in micrometers). 2.5µm particles are considered more dangerous, but 10µm include fine pollen and mold spores, and 1µm may include smoke, smog, and even viruses. You can see the sizes of all sorts of particles your lungs might encounter.

And of course, this cartridge also measures volatile organic compounds. A rough definition might be things that you associate with fumes. But also offgassing from ripening and rotting fruit. Put next to a bowl of fruit, it starts rising.

Next I tested how sensitive it is to cooking cashew pepper chicken. You can see just when I started frying the nuts in spices, and then a few minutes later when I started the chicken. Does this indicates that the VOCs are lingering in the air well after dinner? It still smells good.

Temperature probe

This board is fairly simple, and it’ll use a thermistor (stable and accurate) that will be able to measure temperatures up to 500ºF (260ºC). We’ve got a lot of experience making good thermometers.

Our prototyping experience with this is a snapshot of why tariffs alone will not bring manufacturing back to the US.

Spectral

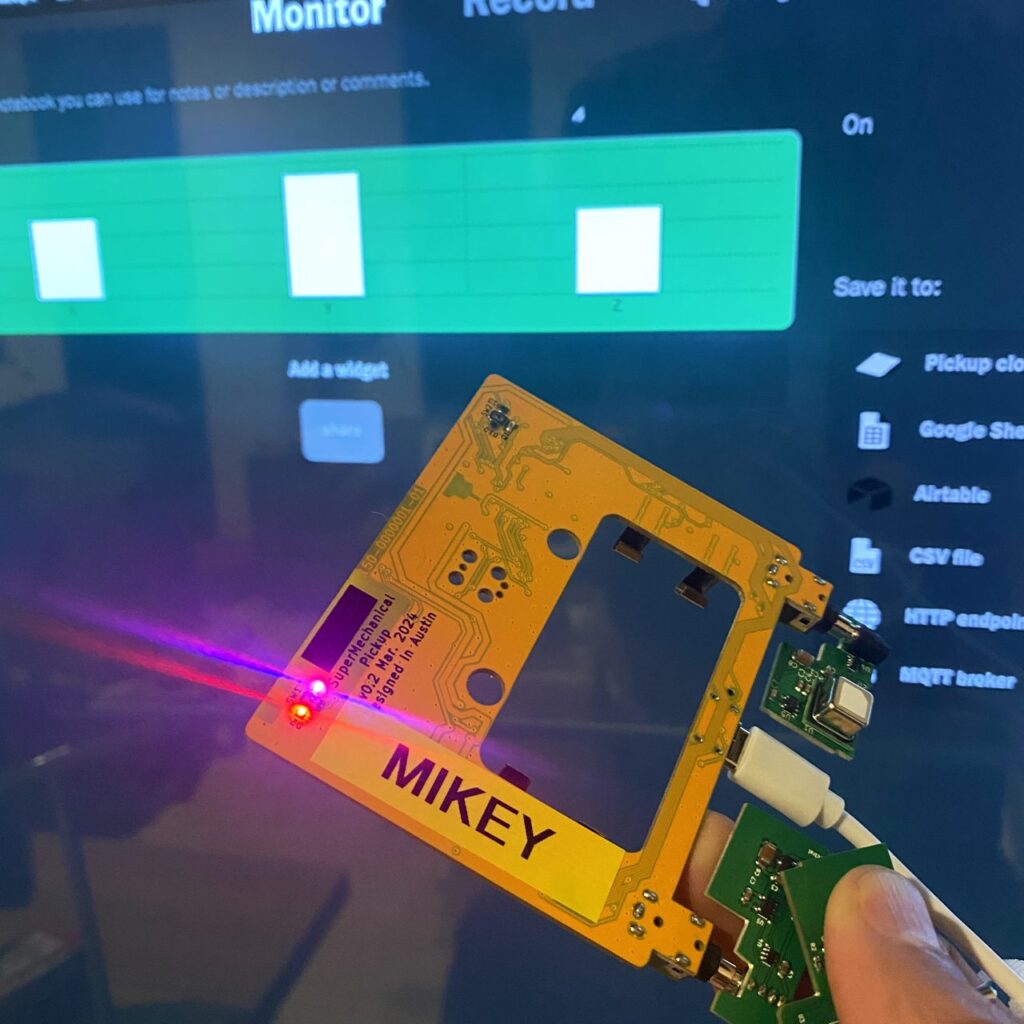

This cartridge is the most interesting, which is good and bad. Bad, because it’s got more parts that have to fit together in a small space, and optical material options to test against each other. Good, because this cartridge is full of potential. It’s got two modes: Slide the diffusion lens on to collect ambient light across eight wavelengths, and pop it off for reading colors. It’s neat to see it react in real time.

I tested three candidates for the diffusion lens, which has to collect ambient light from a wide range of angles without affecting the wavelengths much (you don’t want your lens to be a prism when you’re measuring the wavelength of the light). I compared how they diverged from the raw, naked sensor in different lighting conditions.

Reading colors takes a different approach. No lens; instead we turn on full spectrum LEDs, and the sensor measures what wavelengths from those lights reflect off your target. To prevent unknown light sources from messing up the reading, you need to hold the target surface as close to the sensor as possible. But it’ll be interesting to see what uses we all come up with. You don’t have to be measuring an exact color; you might measure the concentration of a liquid or detect a change in leaf color.

Right now we’re reading uncalibrated values, but given that, pretty neat that it reads some colors accurately. Next step is to work on the calibration.

Jeremy’s been wrestling with filtering the signal from the soil moisture sensor. Guess there’s a reason that most don’t use the capacitive kind of sensor. It’s a bit sensitive to what else is happening on Pickup, but that sensitivity is what makes it a nicer soil sensor.

No production party yet

We’ve heard from our local molder, and there’s no movement with the mold maker of late. Obviously, the unstable state of global trade is compounding the issue, but this is unacceptable, and it’s stressing me out right now.

But we’ve developed two contingency plans and are making adjustments to take control of our destiny and start moving forward again. Our money is already committed to production parts. Ugh—sorry that you have a front seat for the Why You Shouldn’t Make Things show. We still appreciate your patience on this journey.

Crossposted from Pickup Kickstarter update #15