Slow progress lately. Maybe it’s the summer schedule. Maybe it’s because I’m back on the mechanical track.

Multi-jet fusion: it’s different

The new printed parts took a while to get to me (I suspect they had to reprint some), and I’m painstakingly measuring expected vs actual critical dimensions (an engineering term meaning the dimensions that are, uh, critical enough that the manufacturer has to catch any parts that fall outside of the tolerance) and running the various mechanical tests.

Because we’re switching to a new material (nylon, which is pretty resistant to wear and chemicals, while being more flexible) with a new process (it’s not quite as solid as injection molded plastic—there are tiny pores), we have to reexamine our environment performance.

Nylon 12 has very good impact and chemical resistance. It’s considered as having moderate resistance to UV radiation, and the black color helps somewhat. Beyond that we don’t have the option of anti-UV additives like we did with injection molded polycarbonate. We’re constrained by the available materials for MJF and cost.

Nylon 12 is pretty good at not absorbing moisture, for a nylon. But I think those pores in the printing process lend themselves to wicking moisture. Easily solved by making the walls thicker (which has to be balanced against volume, which drives MJF cost) and by using a new (to me) nylon material that comes out with a smoother surface, no post-processing needed.

The standard material has a more pebbled texture that befits a power tool and hides the grain of additive printing. Smooth material has a more even surface that should be more water resistant and just looks really nice. But as demonstrated by the difficulty I had in getting an in-focus photo this close, it’s a really fine difference at this scale.

Injection molding is a miracle of mass production, both cheap and accurate. In my experience, additive printing has more trouble keeping dimensional accuracy across long parts. Sometimes circles become elliptical, sometimes there’s just some warping where you wouldn’t expect it.

But my experience is limited. This happens in injection molding, too—I just know the right wall thicknesses and where to put ribs to counteract warp, and the molder knows how to dial in the time and temperatures so that parts cool evenly. Perhaps the very top-dollar additive printing methods may be able to meet injection molding’s level of detail, but I have to make features like tabs and snaps somewhat larger, and otherwise designing for a much larger tolerance (i.e. how much off the design can a given part be?).

So no surprise, moving to a completely different manufacturing process is not that easy. I had a head start because I’ve been using MJF throughout the prototyping process, but I’m still learning how to adjust the design to a new process (just when I thought I was done with it, sigh). Additive has far fewer constraints than the multi-dimensional puzzle of injection molding, but some of those constraints are in different places. Ultimately not all of my original specs may be met, but I had high standards to start with. This is cutting-edge manufacturing. With a little more grinding, I’m confident we’ll get to a good result.

Particulate cartridge

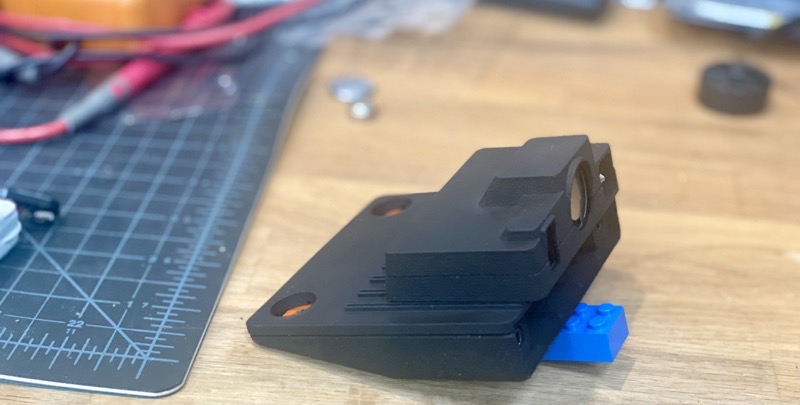

I mentioned in update #15 that we’re using a bigger particulate sensor than we had hoped to. The bigger size, though, requires a way to mount it, because it’s too large relative to Pickup to hang off the back like the rest. I initially was working on a clip-on design, but it was awkward. Changing production methods gave me the chance to copy the ridges on the bottom to the top, and the cartridge can snap into either (as can LEGO bricks, if I’m able to account for the tolerances right).

Temperature cartridge

We had hoped to use the same analog probes as Range Dial, but couldn’t get the reliability we wanted through the cartridge ports. They’re doing a lot of work over four wires to support power, various serial protocols, and plug-and-play.

So we designed another cartridge that handles the analog-to-digital conversion so it can use the same protocol that the other cartridges do. This will give us more accurate results with less developer work. Pretty simple circuit that Jeremy has already tested, and we’ve got production prototype boards coming in from our assembler this week.

Other than that, all the boards are design complete, all components are bought, and ready to be produced at our signal. We’ll do another sanity check with all the new MJF case parts once the nylon dust is cleared, and Jeremy needs to finalize and ship the test rig (discussed in update #9).

Software

We’re doing a lot of unglamorous work here. Jeremy’s been setting up certificates for secure connections between Pickup and our server, I’ve been finishing a bunch of database tasks, and we’ve been making things more stable in firmware and web app. Next is getting all the code up on the server, and hammering out the many more bugs that will uncover. I hope to have a software-centric update soon.

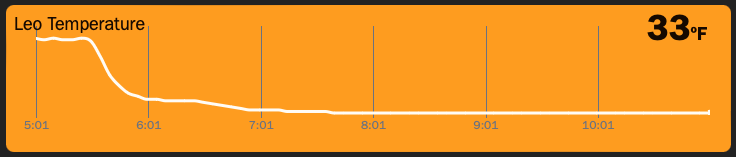

Stuck a Pickup in a cooler to settle a debate as to whether it could keep popsicles cold long enough for a last-day-of-school party without dry ice. (Yes, easily.)

Reading list

I thought the Menswear guy had a nice snapshot of how manufacturing costs translate to retail prices, and how tariffs enter into the equation. Every industry’s different of course, but it gives you an idea of all the roles involved in getting a product to market.

A comprehensive use case of the challenges of making a product in the US (video) that echos some of the same things we’ve discussed in updates. The point about ripoffs at 9 minutes is why I’ll never put a product on Amazon again, even if our products are too complex to copy. He doesn’t say whether the silicone mold at 27 minutes was made in the US, but if it was, the cost would be $40K-50K. I have mixed feelings about the focus of making everything down to tooling in the US—the downward pressure on wages is intense regardless of job type—but I agree with the general direction of keeping things in the neighborhood when possible.

Crossposted from Pickup Kickstarter update #17