forum.supermechanical.com

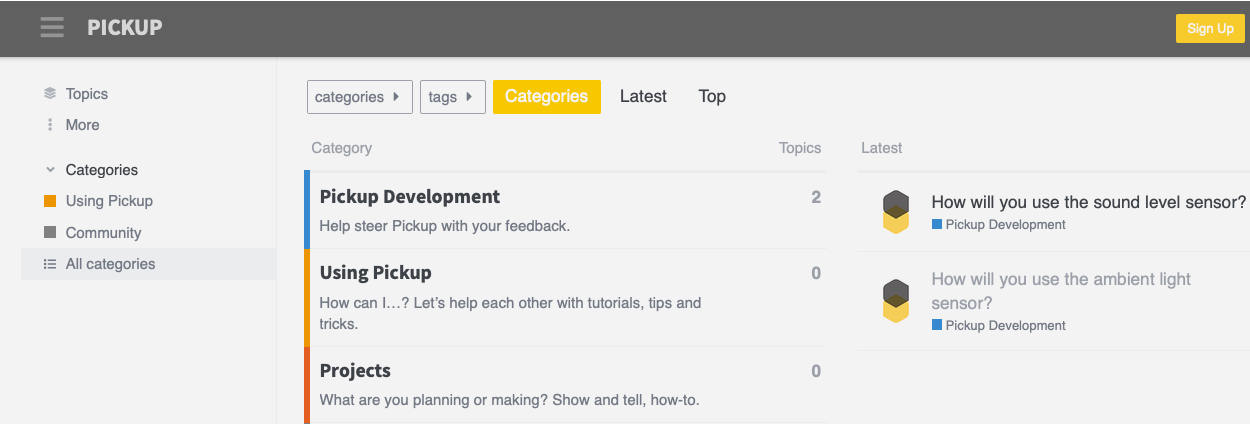

The messageboard is up. We want this to be an energizing place where y’all can share ideas and projects, help each other, and influence Pickup’s future development.

To start us off, we have a few topics we’d like your input on. You may remember from the last update that Jeremy was working on the range of the light sensor, and previously he showed off sound level testing. Help us make sure these work well for your use cases by telling us what you’re curious to try (“I won’t use that” is a useful answer too):

Poll: How will you use the sound level sensor?

Poll: How will you use the ambient light sensor?

And start your own topics if there’s anything you’re excited or curious about. If you sign up for an account with the email address you gave Kickstarter, we’ll be able to give you a badge noting you as a backer.

Electronics

The production candidate boards came in this past week! Big milestone. It’s been a little slower than I’d like, but the board maker is asking questions and digging into the details, which is a promising start to our relationship. One of the first things they caught was a too-small component:

Oh well. As anyone who’s ever made 1000 of something knows, that’s why you prototype the process as well as the product. No harm—this one isn’t critical to operation at this point.

There may be a few minor changes in the final final boards (and, uh, parts list), but the functionality is all there. Jeremy did a great job changing out the engine of Pickup this quickly, and he already started coding firmware blind while the boards were getting made because he knows this new microcontroller well. He’s now working to get it up and running (electrical engineers call this “bring up”).

Industrial design

The board shipment unlocks me here. I haven’t gotten the expensive final prototype printed yet because I was waiting for the boards to come back to us, but I wasn’t idle while waiting. I kept working on refining details, testing and printing another half dozen versions since the last update.

I did order nicer prints that are an intermediate level between our in-house printer and that fancy PolyJet. SLS (selective laser sintering, a tech first developed here at UT Austin) parts have a higher accuracy to both the design’s dimensions and the flexibility of the final material, which is helping me check fit on a couple things. This process is less prone to warping the big thin parts than the Form—the SLS printer fuses powder in a tub full of it, so the parts are well supported, whereas printing on SLA printers like the Form introduces stresses from sticking to the build platform and support structures that you break off afterward (that also messes up the surface, affecting fit).

Software

While the hardware wheels have been turning, we’ve also been working on the cloud component that hosts our software and your data (as a convenience—you don’t have to use it). We’ll go into the details in a later update, but we’ve been laying the foundation and testing it as we use it to test the prototypes.

Okay, back to work. Don’t forget to check out the forum.

Crossposting from Pickup Kickstarter update #6