Apologies for the later update. We’ve got slow but real progress on mechanicals and production test systems.

Mechanicals

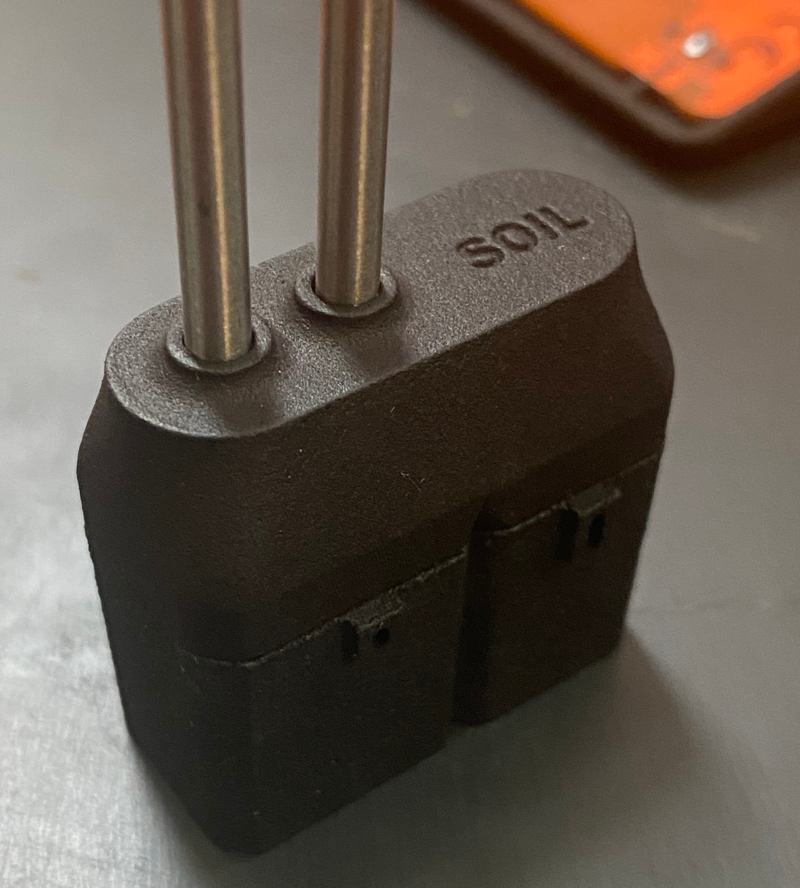

Another round of parts just arrived in the mail, as I try to adjust the design for MJF printing. MJF is not as stiff as the injection molded polycarbonate and doesn’t handle the fine details as well, so I have to make features that fit together bigger and blunter. Some parts snap together great, and some will need another pass. But things are mostly looking good, except that we may not get the same water resistance we were going to get from injection molded parts—particles fused together are somewhat more porous.

Buttons

The buttons present some additional challenges. MJF printing costs are mostly correlated to material volume, but there’s a minimum price so small parts aren’t as economical. The whole point of moving away from injection molding was to remove those fixed tooling costs for our low quantities (and uh, a disappearing toolmaker). And MJF doesn’t do translucent, which we need for LEDs to shine through.

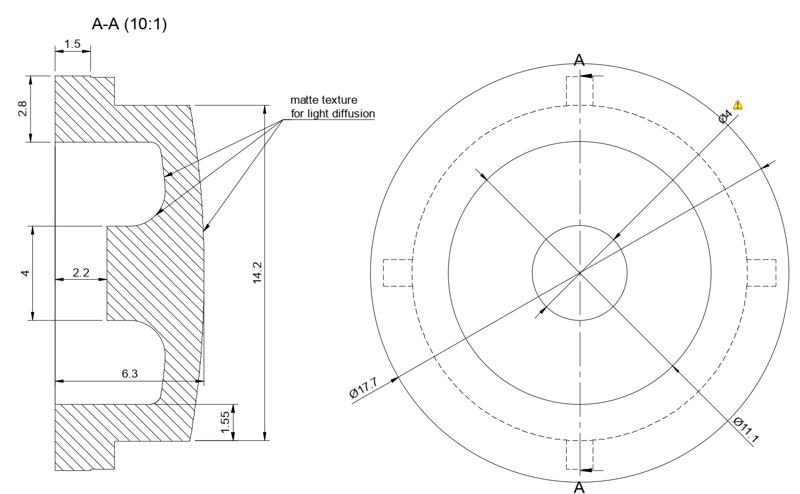

So I started looking into silicone buttons for their feel and sealing properties — I’d be able to eliminate the o-ring I had in there. Normally silicone molds are even more expensive than for thermoplastics, with the need to heat the molds for curing and even tighter tolerances. Luckily there’s a much less expensive way to mold silicone.

Compression molding uses less pressure, which means the tooling is cheap. Briefly, you put dollops of uncured silicone in the heated mold and close the halves. No big presses needed, no molten plastic injected at precise rates.

I looked at some stock buttons, but they were also missing a hard, narrow post to press down on the microswitches on Pickup’s circuitboard. Silicone is too squishy, but the common thing to do is overmold (that is, place a part into the mold that gets stuck onto the completed molded part) a tiny carbon disc. This is stiff, and also conductive so that you can touch it to electrical contacts right on the circuitboard to eliminate the need for switches (which we’re leave on our own board for now).

I got some sample parts to study, drew up one of my own, and got some quotes. It’s simple enough that I’m skipping the prototypes before tooling — it’s hard to prototype the material well unless we make a mold and cast silicone. The supplier I picked will be able to do silicone buttons, including the mold costs, for about half what I was planning for printed parts. I’ve got an order in for a mold for the buttons, and hope to get samples in 2-3 weeks.

Test rig

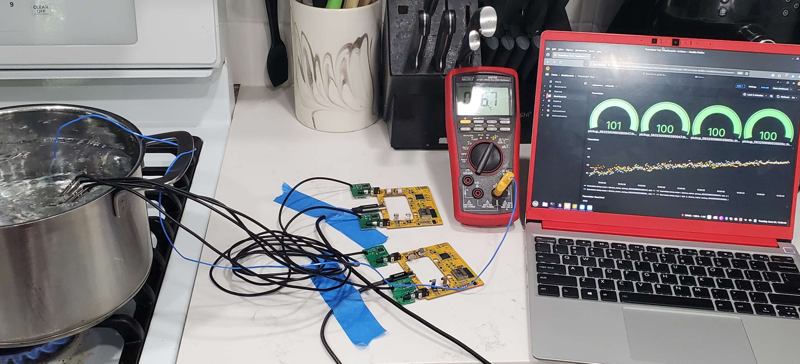

We’ve mentioned that the test system that checks each Pickup board is a product unto itself. Now it’s even got its own case that Jeremy printed. This has a slot for a Pickup board to slide into and aligns the sensors with test systems (i.e. an LED for the light sensor, and a buzzer for the sound meter).

Jeremy also would like to register his extreme frustration in getting the system to do what it needs to do, reliably. He’s taking the tooling that chip manufacturers have provided, but where it may hold up for the developer uploading firmware to the board on their desk, it’s harder to make it work thousands of times while being operated by a non-technical person in an assembly line.

The test system should be ready to ship to the assembler in the next couple of weeks, and then they should be able to crank boards out.

Cartridges and sensors

All the cartridge boards are done, except the temperature cartridge since we switched our plan on that one more recently. But the temperature prototype boards are looking good, so I think we’re about ready for production on all cartridge electronics.

This may be an insane level of commitment but we’ve successfully got sensors from Twine (y’know, our 13-year-old sensor box) running on Pickup. Existing magswitches and breakout boards will be readable by your Pickup.

Working

Jeremy and I continue to plug away at Pickup, but it’s not our full-time job right now. We’re both consultants so we do have more dead time than a normal full-time worker, and we do live/sleep/breathe this product, but it does not pay the bills yet.

With the string of challenges we’ve covered in our updates, we’ve had to think on our feet to keep money in reserve to finish production, and at least we’ve been successful in this. It’s just come at the cost of more of our time and schedule, and paying ourselves. It’s always possible that there will be one too many challenges thrown our way, but as of right now we’re still on track to ship the first production run of Pickups to you this year. Thanks as always for your understanding—this has been a trying project, but it’s come with the best group of backers we’ve ever been lucky to have.

— John

Crossposted from Pickup Kickstarter update #18