We’re in that lull I warned about last update. We’ve been focused on production setup, and such a range of emotions we’ve been through.

Buttons

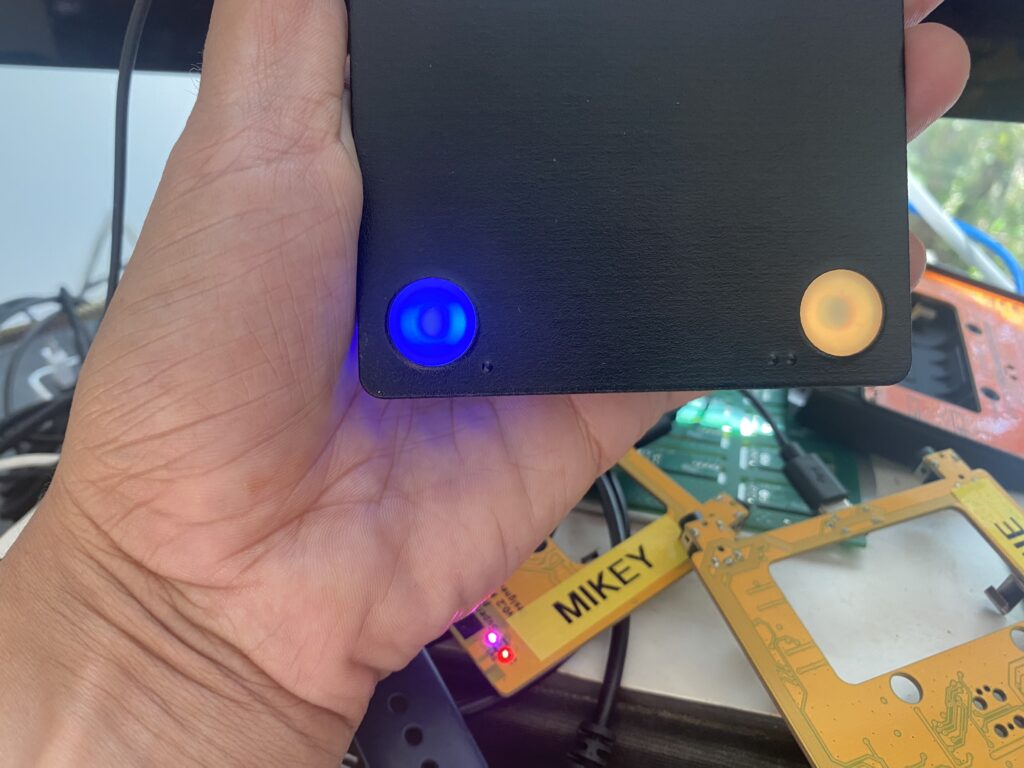

Exciting! Got sample silicone buttons. They fit nicely and diffuse light well.

Disappointing! The action on these is really stiff with too much travel. That’s okay—this is why we get samples.

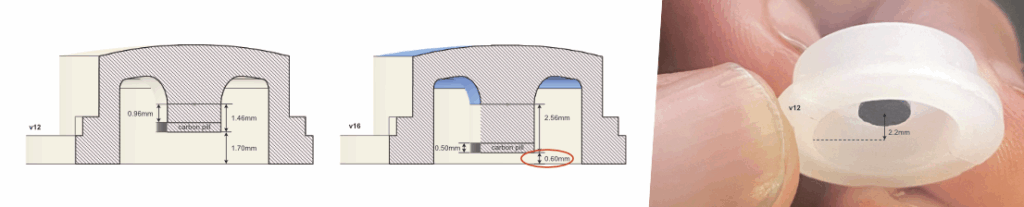

Exhausting! I’ve been working with the molder on an adjustment to the mold—just making the post in the button that presses the switch on the circuitboard a little longer. But here’s one of my least favorite parts of getting foreign-made parts—communication.

I’ve got experience in this. You can usually use engineering drawings to be unambiguous. We’re just stuck on the difference between what they’re telling me should happen, and the suspicion I have will happen based on the samples, and the difficulty may be between the language barrier (their English is better than my non-existent Mandarin) and that I’m not talking directly to the engineer. But I think we’ve sent enough drawings back and forth now, and we’ll be okay.

When you get a good working relationship with a manufacturer, whether overseas or domestic, you hold onto that. Between the time since our last product, and doing new things, we unfortunately have had to requalify our sources, and then do it again as circumstances have made us shift plans. I tell myself it’s all adding to our toolbox for future products and improvements. Pretty much all our suppliers know their stuff and have excellent quality—it’s often just us learning about their processes so that we know what we’re asking for.

Shipping

Confusing! In these unstable tariff times, I’ve given up on predicting what we’re going to get dinged. So when I got a bill from Fedex for duties, I braced myself. It was $.43. That’s… great? Not when you see that it’s for the button samples, which were valued at $1. So when we place the big button order, we’re looking at a 43% surcharge. The reason this is mostly unnecessary friction instead of anything that’s going to change manufacturer behavior is that even with that tariff, the buttons are several times cheaper than I could find in the US.

More of this good news/bad news happened with that diffusion lens that suddenly wasn’t available to US buyers. I guessed that it was because tariffs had made it too complicated for them so they blocked orders to some countries while they figured it out. Looks like they have, because I was able to finally place that order. (But thank you to the European backer who offered to buy them on our behalf.) In the meantime, they had made the shipping cost about three times the cost of the parts, so looks like they figured out the customs part well enough to communicate it upfront. Luckily this was an inexpensive part, but these fees will add up.

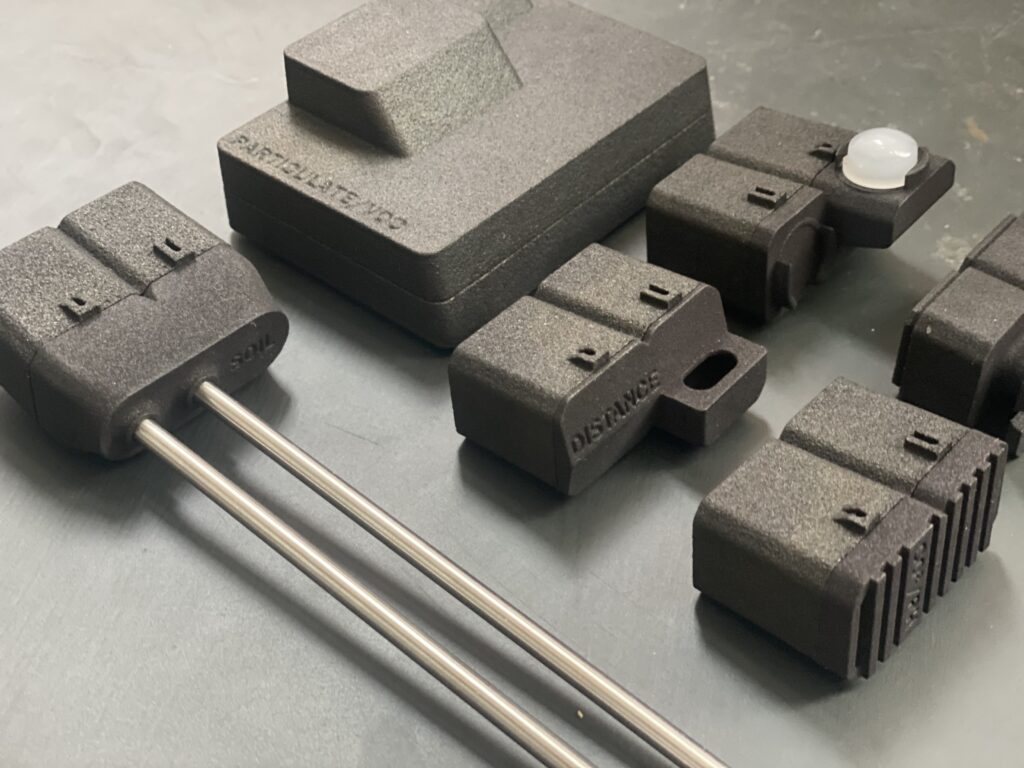

Some golden master parts

Just got in these printed parts with the goal being to check that they’re ready to go into production. Almost every sensor cartridge has gotten the last sub-millimeter nudges, and look great with a two-tone texture. A few are waiting for circuitboards with matching dimensional changes to confirm the fit.

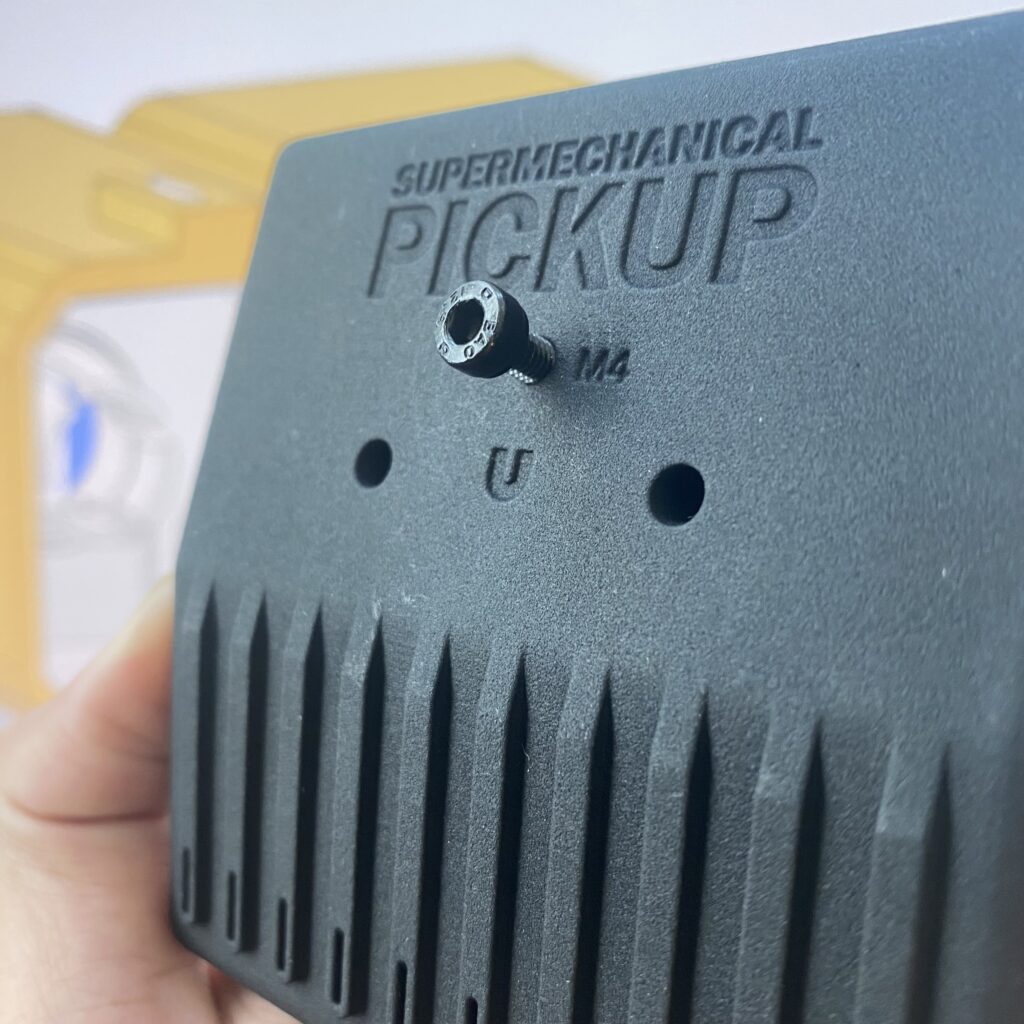

The only adjustments left to make for the switch to MJF production are on the Pickup case’s snap fit and rigidity (this process has been more prone to warp).

I’m getting pretty good at designing for the MJF nylon material properties, so these parts have solid snap fits that mostly eliminate the need for additional assembly steps like adhesive. A neat thing about additive manufacturing is that it makes screw threads easy to mold. So I was able to eliminate a $.40 brass insert plus the labor and equipment to press it in. Handy for tripod or rack mounting.

Manufacturing rig

After hammering out bugs and a lot of testing, the rig for our assembler to give us working boards is ready. But time was tight to get it shipped before Jeremy took a trip, and the assembler’s on holiday for a week anyway, so Jeremy decided to wait until he got back to be sure he didn’t miss anything. Don’t want to ship that back and forth again.

Use case

One of my most frequent personal uses of Twine and now Pickup is monitoring the conditions of pets. It’s easy to throw an outdoor-friendly battery-powered sensor in a habitat when I want to keep an eye on freezing water or extreme heat. Just got some fall chicks—when they’re young, they need to be kept warm, and while it’s been hot enough lately to go without a heat lamp during the day, it’s nice to get an alert to turn one on when the temperature’s dropping in the evening.

So lots of little ups and downs, but nothing we haven’t encountered before at this point. We’re just hardening ourselves to it to focus on each next step until we’re done. Next update we should have everything released to production, and we can talk more about software.

—John

Crossposted from Pickup Kickstarter update #19